Processes

Getting material and packaging

The fresh paddy from the field will be brought into the factory after it has been checked for satisfactory quality.

Received packaging will be checked for accurate marks, specifications and integrity, ready for use in the next steps of the production process.

Drying by heat

Fresh paddy is put into the kiln through a conveyor system, then spread evenly in the kiln and dried until it reaches the prescribed humidity which produces dry paddy.

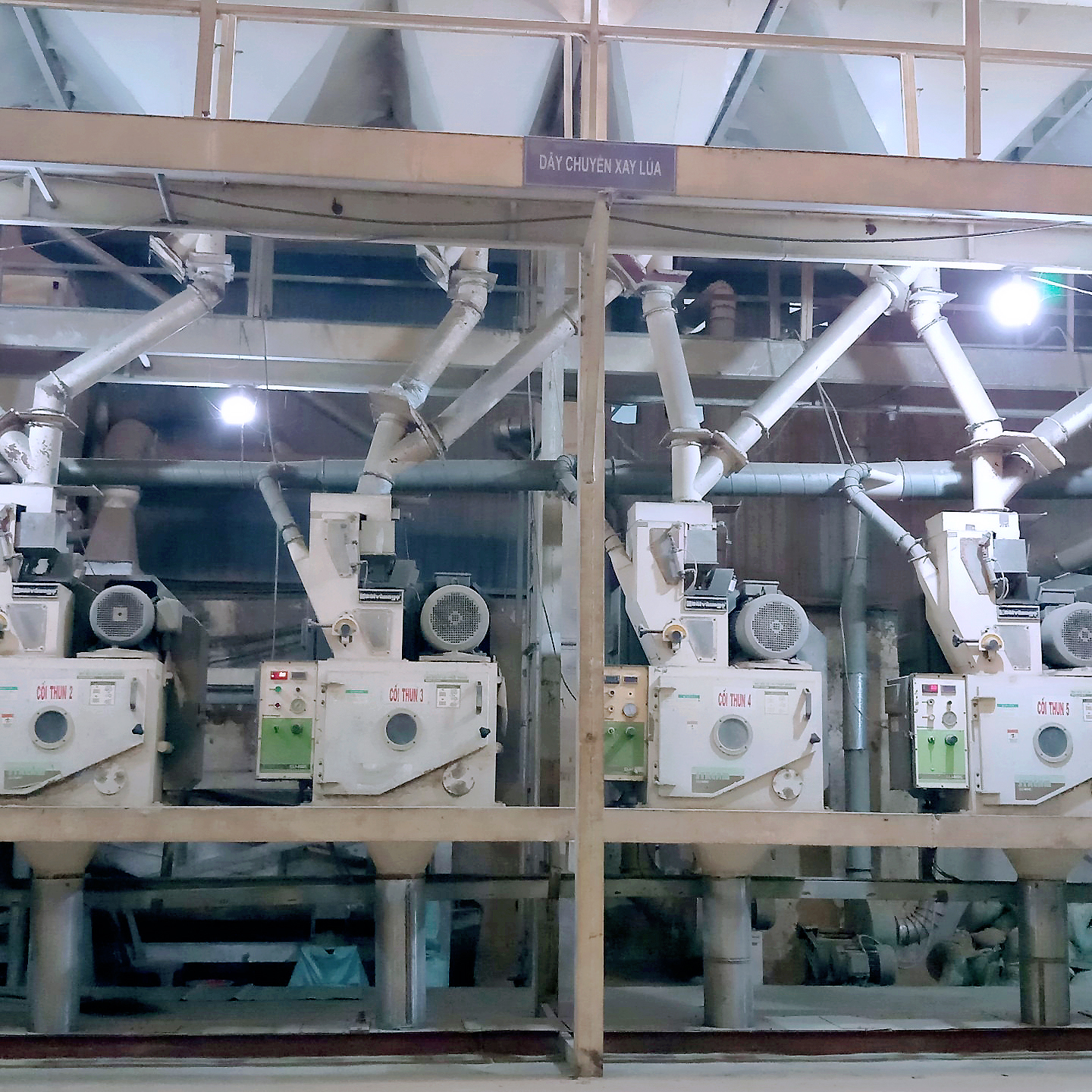

Husking

Whitening and Polishing

Grading rice and brokens

The whitened and polished rice is transferred to the grain separator / grain selector to produce a product with the required standard brokens ratio.

Sieving, Sorting and Hoovering

Before weighing - packing, the rice will be passed through the impurity separating system, then passed through an optical sorter machine to remove unqualified grains (chalky, yellow, damaged, red and streaked kernels,...), and through a vacuum system to ensure clean and safe rice.

Weighting and Packing

Weight rice with the automatic scales before being packed on demand of customers.

Detecting metal

After packing, transfer the rice to the metal detector, to remove any leftover metal in the product before delivering.

Delivering

The sacks/bags/boxes of the finished rice are loaded onto clean and ventilated transport vehicles with rain tarpaulins to the stores, distributors' warehouses, or packed directly into the containers at our factory for export.

Business license number: 1601265958

Dated: 16/12/2009

Issued by Department of Planning and Investment of An Giang Province, Vietnam

Copyright © 2020 TVFOOD Co., Ltd.

Address: Nhon Hoa Hamlet, Nhon My Commune, An Giang Prov., Vietnam

Representative Office: 69 Thanh Thai Street, Dien Hong Ward, Ho Chi Minh City, Vietnam

- Phone: +84 28 3866 1797

- Hotline: +84 913 848 116 (Ms. Ngan)

- Email: info@tvfood.com.vn